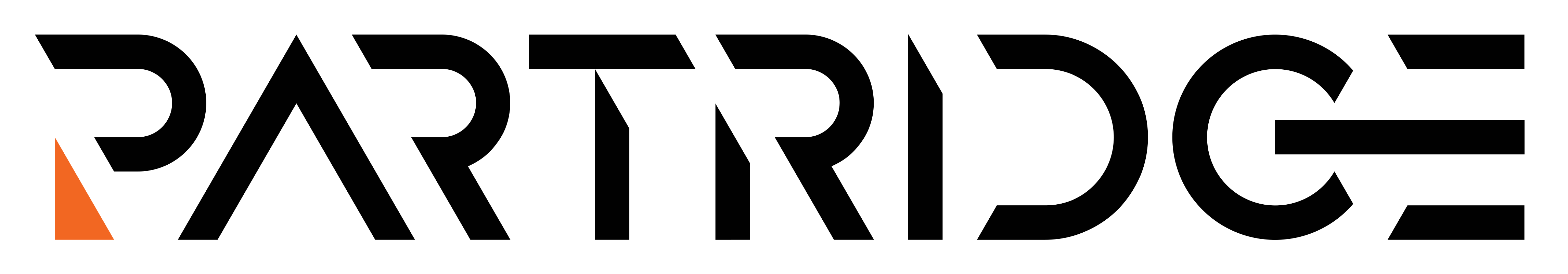

Client: Earthbuilt Technologies

Designer: Crest Robotics

Location: Sydney, NSW

At Partridge, we’re always interested in innovative approaches to structural engineering, and Earthbuilt technology presents an unusual and compelling method for constructing walls from loose particulate materials. Unlike traditional masonry or concrete, Earthbuilt binds sand, clay, gravel, or even recycled materials with a tensile membrane rather than firing, cement, or chemical adhesives. The material is extruded layer by layer, forming continuous walls that are structurally resilient under loads and environmental stressors.

Partridge is currently assisting Earthbuilt to refine and develop their technology, offering engineering expertise to optimise structural performance and material application. On Earth, this approach allows rapid onsite construction, reduces reliance on imported materials, and can incorporate recycled waste streams into the structure. Early testing indicates promising performance in bushfires, floods, and even seismic events, highlighting the robustness of this “reinforced earth” principle.

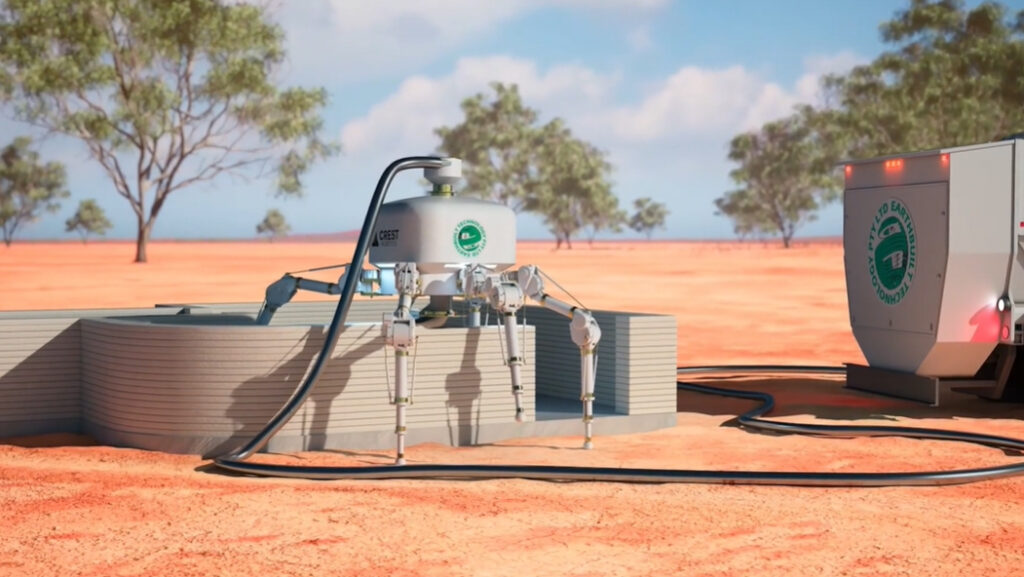

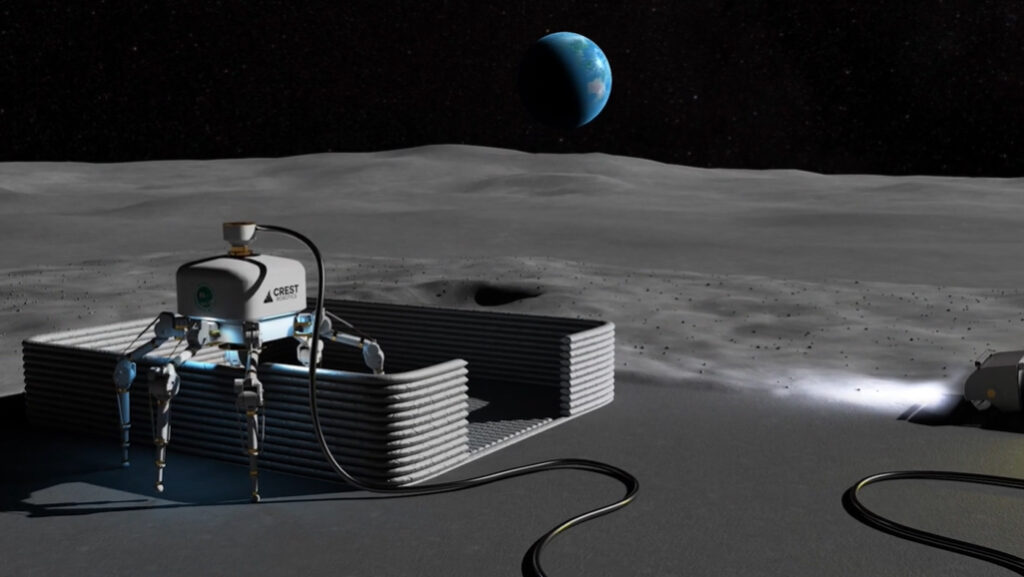

Some proponents have suggested that Earthbuilt could eventually be adapted for lunar construction. In theory, the low-energy, layer-by-layer extrusion process could make use of local regolith and avoid the enormous costs of transporting traditional materials from Earth. However, this remains highly speculative. The Moon’s extreme temperature variations, low gravity, and vacuum environment introduce unknowns that would require significant research and engineering adaptation before the technology could be considered viable off-world.

For now, Earthbuilt is a fascinating example of how rethinking the fundamentals of structural systems can produce resilient, sustainable solutions on Earth. Its potential applications in space are an exciting prospect, but one that should be approached with caution and rigorous engineering assessment.

https://crestrobotics.co/charlotte_iac_2